Earthworms play a vital role in maintaining healthy soil. They continuously move soil, loosening and aerating it, aiding water infiltration. Moreover, the waste products they leave behind during the process of feeding on nutrients provide valuable fertilization.

Despite these benefits, earthworms pose significant challenges for greenkeepers/ turf managers. As they expel waste, small worm casts appear on the soil’s surface. These tiny mounds not only affect ball movement on golf courses but also create an unsightly appearance. During milder months, when worms are more active near the surface, these soil casts can accumulate, resulting in additional work for greenkeepers/ turf managers.

Until 2019, greenkeepers had a straightforward solution to tackle worm casts. However, since the ban on Carbendazim due to its potential toxic effects on the human reproductive system, no clear chemical replacement has emerged.

How Worm Casts Affect Cylinder Mowers

Worm casts are not merely an inconvenience; they cause several issues, particularly when using cylinder mowers.

Due to their wet, sticky nature, worm casts clog mower rollers, eventually causing them to become uneven affecting the height of cut.

Additionally, worm casts cause an abrasive grinding paste to form between the base blade and cylinder reel. This blunts the cylinders and base plates so that regular and costly sharpening is required. If the sharpening is not completed the blunt cylinders affect the overall cut quality and presentation of the course. For many greenkeepers, this means their cylinder mowers spend more time in the workshop than out on the course.

While strategies like delaying the cut until the middle of the day to reduce stickiness, brushing the turf prior to cutting, or using an older mower when cast levels are high can help, these are not practical solutions as they add time and expense to the ongoing task of turf maintenance.

Using a Trailed Rotary Mower

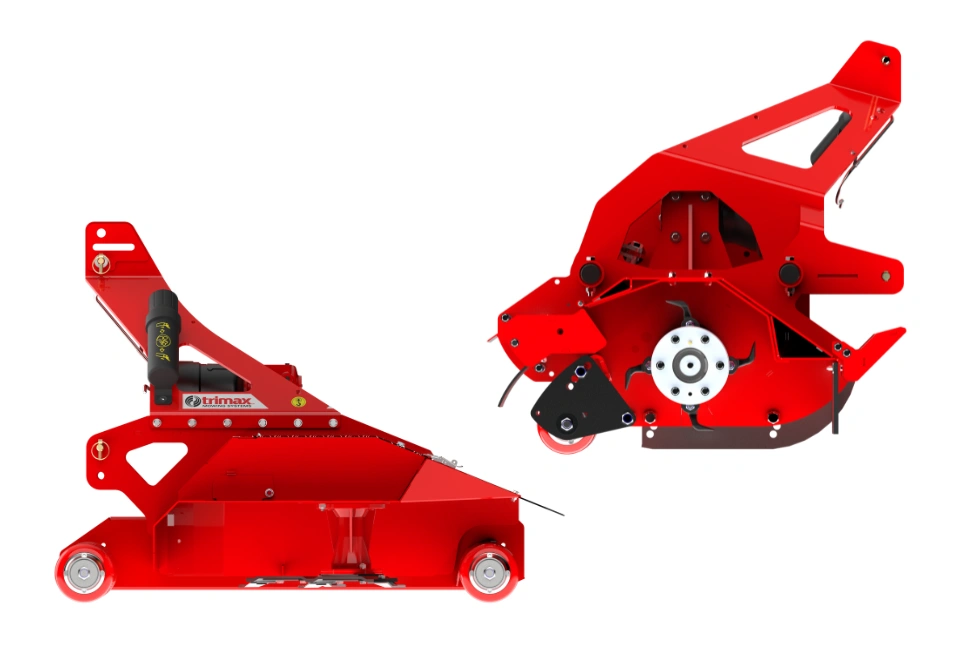

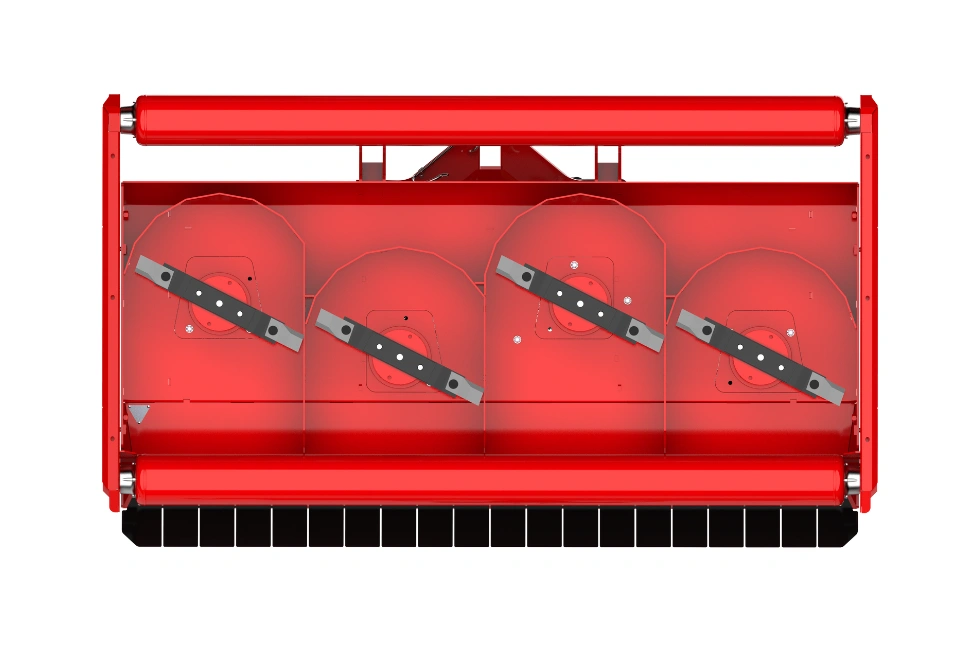

Until a solution is developed to control worm casts on turf, one time-saving way of tackling them is to use a rotary mower. Trailed rotary mowers do not encounter the same problems as cylinder mowers, as they have been engineered to perform in a wider range of conditions with unwavering reliability.

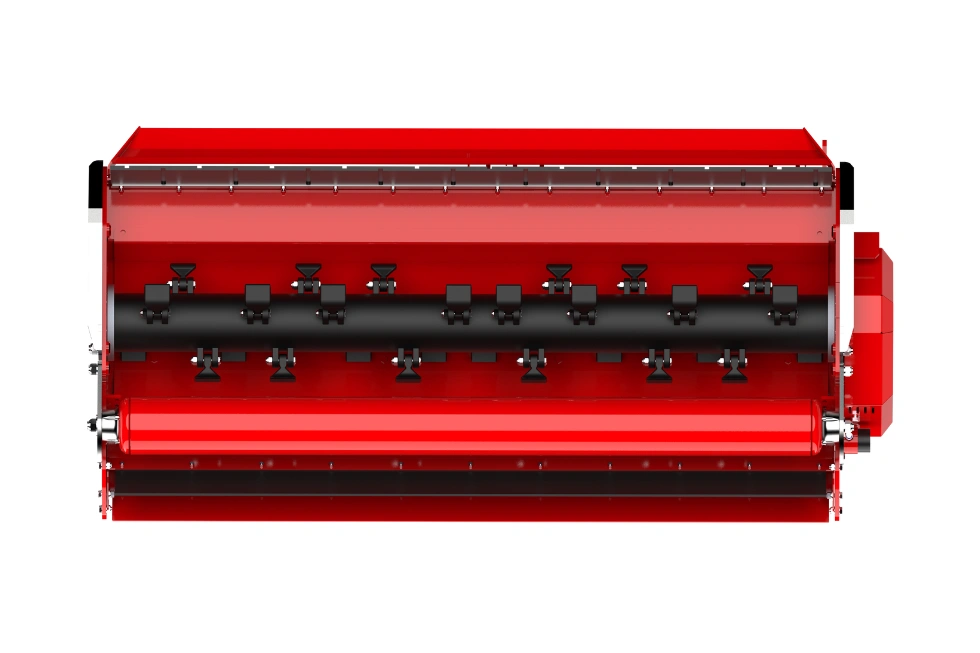

Most trailed rotary mowers have 5” diameter smooth rollers which are nearly three times larger than a cylinder mower, providing strength when it’s needed most. These rollers are fitted with scraper wires (either a thin metal wire hugging the roller or a solid steel bar running across the length of the roller) which provides constant pressure across the roller, for keeping it free of debris and worm casts.

Trailed rotary mowers also offer a high spindle speed and airflow, this helps keep the blades clean of worm casts, enhancing cut quality, and reducing maintenance costs. Another consideration is cleaning, which is made easier with a trailed machine as the decks can be folded vertically, providing clear access and eliminating the need to crawl under or bend over the machine.

To witness how a trailed rotary mower performs on your worm casts, contact Trimax at +64 (07) 543 1895 or visit their website https://trimaxmowers.co.nz/book-a-demo/