When it comes to ensuring your equipment performs reliably, regular bearing maintenance plays a crucial role. At Trimax, we’ve recognized the challenges our customers face with traditional greaseable bearings, particularly the maintenance required to prevent to debris ingress. That’s why we’ve developed the Titan Bearing System—a groundbreaking innovation designed to deliver superior performance with no maintenance needs.

The Problem with Traditional Bearings

In traditional greaseable bearings, the primary defence against debris is regular greasing, which flushes out contaminants and ensures smooth operation. While this approach is effective, any lapse in the greasing schedule can lead to premature bearing failure, resulting in costly downtime and repairs.

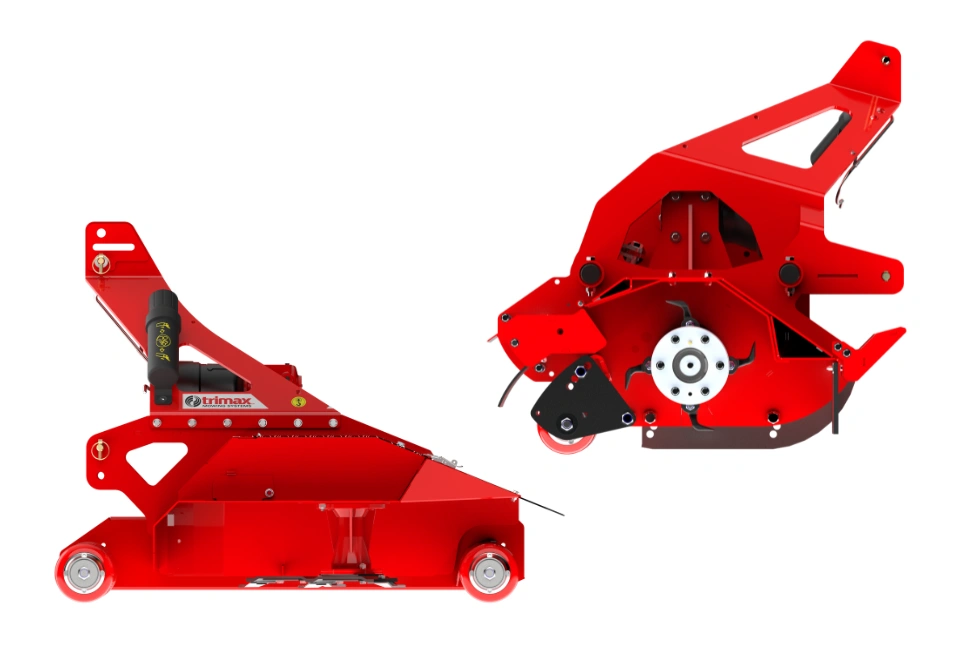

The Trimax Titan Bearing System

The Trimax Titan bearing system is engineered to overcome these challenges, providing a maintenance-free solution that outperforms traditional bearings in every aspect. Here’s how it works:

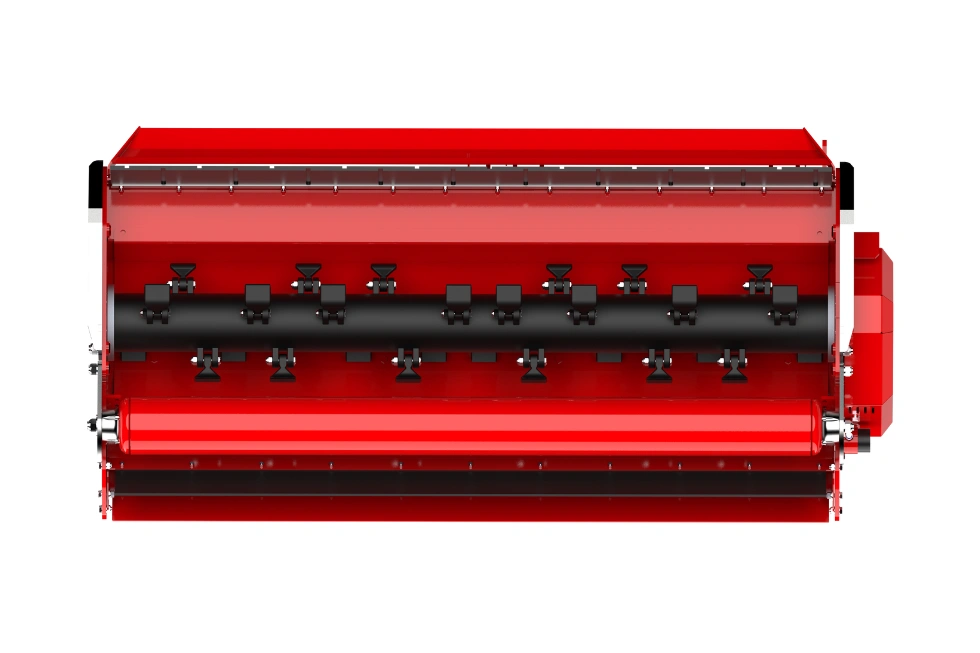

1. Multi-Layered Sealing:

The first line of defence is a five-lip cassette seal, strategically positioned under a pressure plate. This is just the beginning of the Titan’s robust protection. The bearing itself is further safeguarded by a triple lip seal, providing an additional layer of security.

2. Complex Ingress Channel:

The Titan system features a highly sophisticated ingress channel that debris must navigate before reaching the pre-greased rolling elements. With six changes in direction along the channel, contaminants face a near-impossible task of penetrating the bearing.

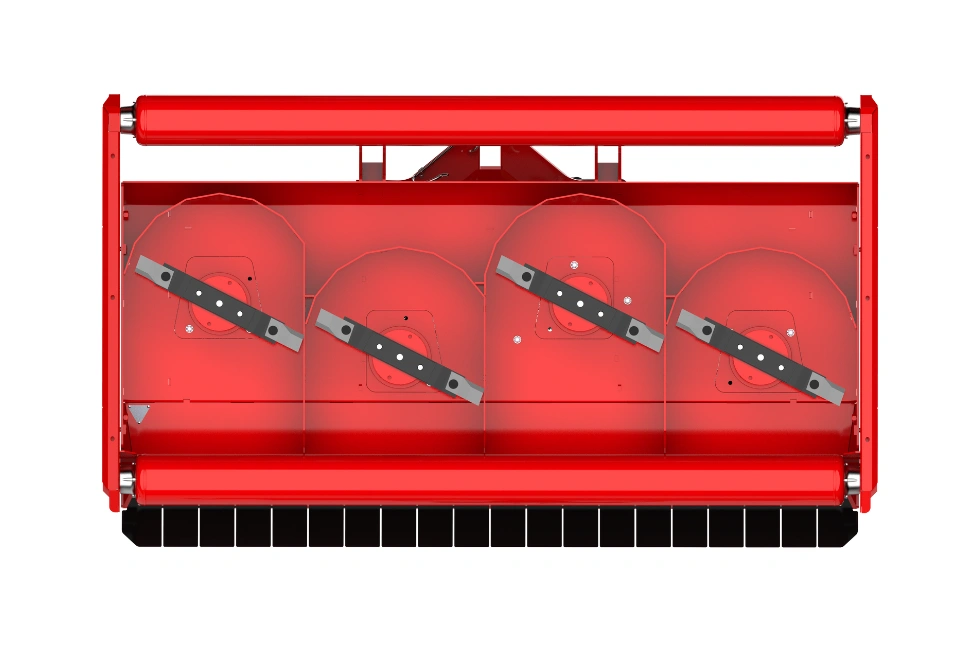

3. Superior Load Capacity:

The Titan bearing doesn’t just excel in protection—it’s built to handle more load. The Titan bearing uses a double row ball bearing set up with twice the load rating of typical single-race bearings in both radial and axial directions. This allows the Titan bearing to absorb greater impacts and perform under heavier loads, making it ideal for demanding mowing environments.

4. Solid Steel Housing:

The bearing is encased in a solid steel housing, which adds to its durability and resistance to environmental factors. This construction ensures that the Titan system can withstand the rigors of intensive use, offering unmatched reliability.

Benefits to Customers: Time, Money, and Peace of Mind

The Trimax Titan bearing system is more than just an upgrade; it’s a complete rethinking of what roller bearings can offer. By eliminating the need for 8-hour greasing intervals, we’ve removed the daily maintenance requirement for operators and technicians, allowing them to focus on what really matters, getting the job done.

Since its introduction in 2020, the Trimax Titan bearing system has consistently proven its value across a wide range of challenging environments. Its exceptional durability and reliability have allowed us to confidently include it in our 3-year warranty, offering you peace of mind.

At Trimax, we are confident that the Titan bearing system will exceed expectations, providing years of reliable, maintenance-free operation.