At Trimax, we have a range of blades and flails designed to help achieve the cut quality you’re looking for, whether you’re mowing turf, managing vegetation, or mulching heavier material. Keeping blades in good condition is one of the most important factors in maintaining performance, finish quality, and overall mowing efficiency.

Regular inspection and timely replacement not only improve results on the ground but also reduce unnecessary stress on your mower and tractor.

When To Sharpen Blades

Blades may be sharpened if the cutting edge is dull but not excessively worn, the leading-edge radius is less than 3mm (1/8”), and the rear upturn of the blade remains intact. These conditions indicate the blade still has enough material and correct shape to perform effectively. If any of these criteria are not met, sharpening is not recommended.

When Blades Should Be Replaced

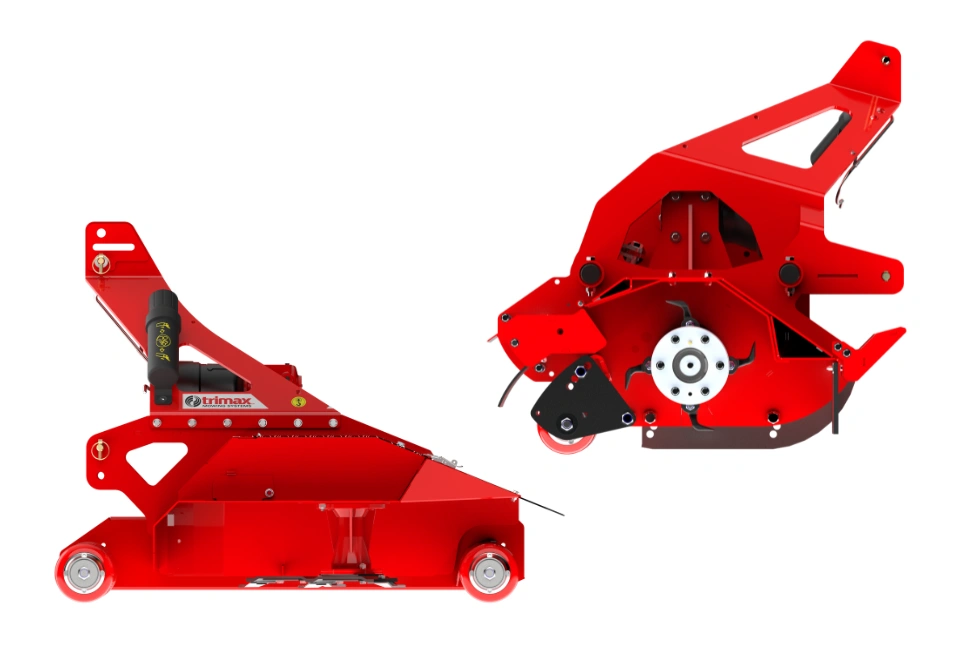

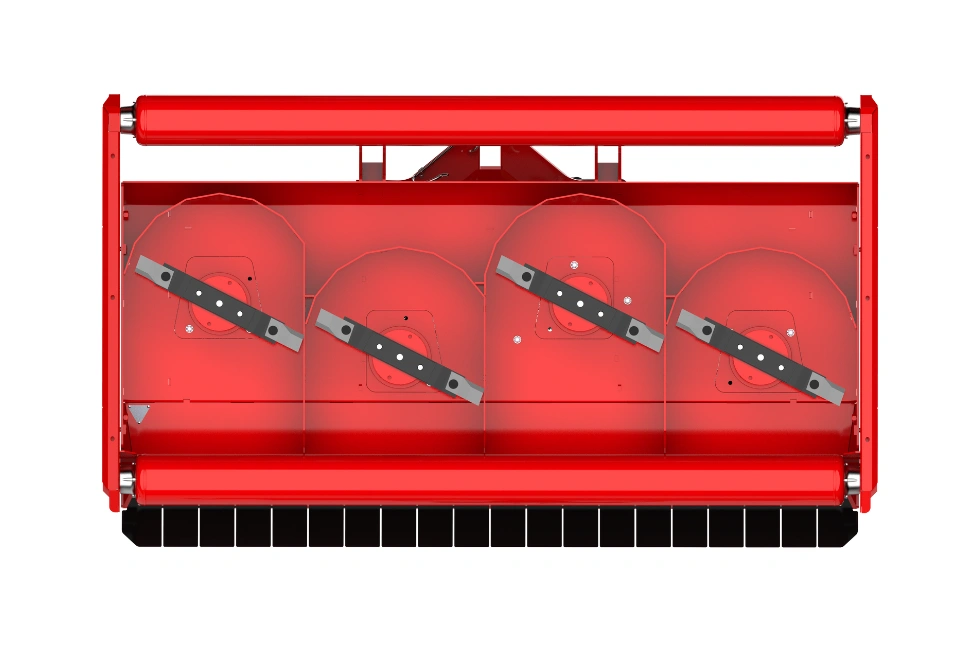

Replacing blades at the right time is critical for maintaining cut quality and protecting your mower. Blades should be replaced if the tip radius exceeds 5mm (13/64”), or if the cutting edge has worn back more than 5mm. As blade material wears away, the blade’s reach is reduced, which directly affects overlap between spindles. Reduced overlap can result in visible strips of uncut grass and a poorer finish.

Blades should also be replaced if the rear upturn has worn sharp or if the crease line shows signs of cracking or excessive wear. These conditions compromise both performance and safety.

Bolts and Nuts: Don’t Overlook the Hardware

Blade hardware is just as important as the blades themselves. Whenever blades are changed, a new Nyloc nut should always be fitted. Bolts should be replaced if there are any signs of impact damage, if the blade or beam is bent, or if the threads or bolt head show wear. Using damaged hardware can lead to imbalance, premature wear, or component failure.

Blade Matching Matters

All blades fitted to a spindle must be matched. Mixing blades of different wear levels or weights can create imbalance, placing unnecessary stress on spindles, bearings, and the mower deck. Proper blade matching helps ensure smooth operation and long-term reliability.

Blade Overlap and Cut Quality

Trimax mowers are designed with a 20 mm cutting overlap between spindles to ensure a consistent and high-quality finish. As the blades wear, this overlap is reduced, which can lead to uncut strips of grass being left behind. Sharpening worn blades may temporarily improve sharpness, but it does not restore blade length and can accelerate overlap-related issues. For this reason, sharpening heavily worn blades is not recommended.

Maintaining correct blade overlap through timely blade replacement is essential to preserving cut quality and preventing avoidable damage.

NexaBlades: Taking Blade Performance Further

Trimax blades are engineered as part of a complete cutting system, and NexaBlade represents the next evolution of that design philosophy. Building on the proven performance of the industry-leading Trimax LazerBladez, NexaBlades have been tested and shown to deliver measurable performance improvements.

NexaBlades improve clipping spread by up to 70%, reduce clumping by 51%, and improve cut cleanliness by 14%. They also require 5% less PTO power, increase resistance to erosive wear by 50%, and reduce aerodynamic noise by 15%. These gains translate directly into better finish quality, improved efficiency, and longer blade life.

Key Takeaways for Better Mowing Performance

Regular inspection is essential. Worn components should be replaced early rather than pushed beyond their limits. Maintaining correct blade overlap is critical for achieving a superior mowing finish and protecting your equipment.

At Trimax, we’re focused on time efficiency. To reduce downtime, we recommend keeping a second set of blades, bolts, and nuts on hand. This allows blade changes to be completed quickly and gives operators a productive maintenance task when weather prevents mowing.

For more tips on blade maintenance, watch the video below.