Behind the Scenes: The Rigorous Safety Testing of Trimax Mowers Unveiled

At Trimax, safety isn’t just a mere checkbox item; it’s deeply embedded in our core values and influences every facet of our operations.

“From the design and development of our machines to the testing and manufacturing processes, safety is always at the forefront of our minds. We believe that by prioritising safety, we can not only protect operators but also enhance their productivity and efficiency.” Caroline Shaw, Global Brand Manager at Trimax.

Here we delve behind the scenes, offering a glimpse into the rigorous safety testing protocols that every Trimax machine undergoes before it hits the market!

Thrown Object Testing

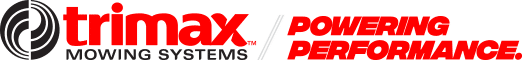

When cutting grass, mowers can come into contact with foreign objects like stones, sticks, and golf balls. When mowers come into contact with them, there is a danger that the struck object may be thrown and cause injury to the operator or any bystanders.

The thrown object test looks at how and where objects are dispersed. During this test, the machine is surrounded by specified targets and will run over sand and stones. To pass the test, no object can be thrown to the side or in the operator area, and only low impacts in the discharge area are acceptable.

Blade Impact Testing

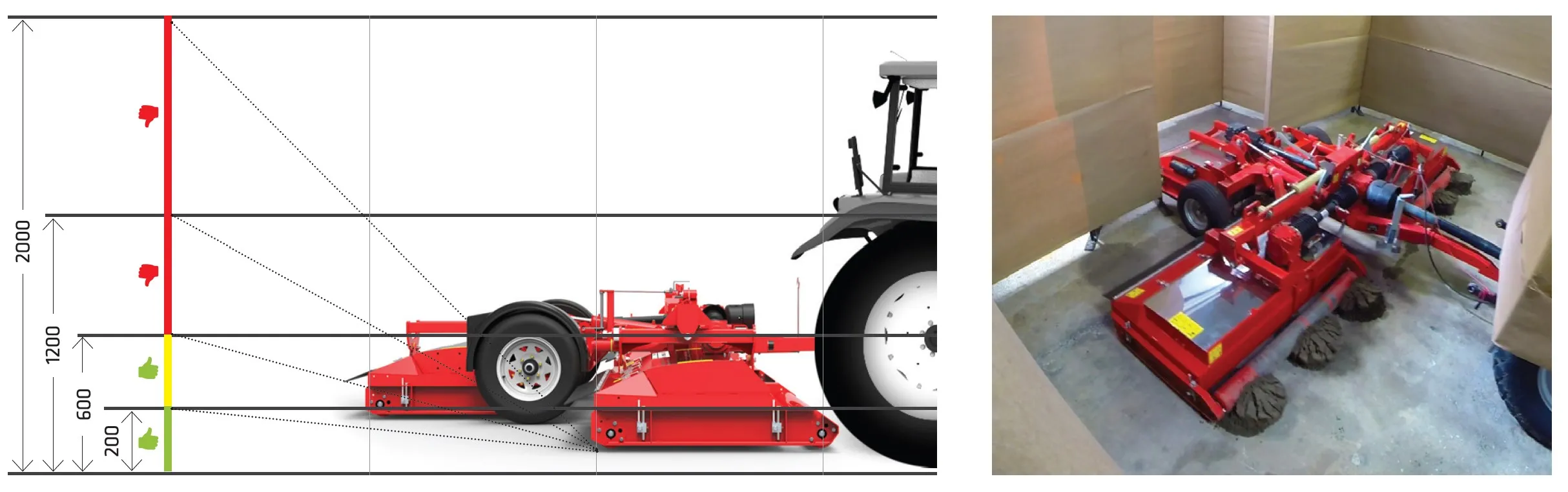

Although Trimax blades are designed and made with durability in mind, in the event of a blade breakage, it must not fall in an unsafe way.

During testing, the mower is surrounded by targets. While the blades are moving, the mower is lowered onto a high-tensile steel bar.

To pass the blade impact test, there must be no loss of any part of the mower, and the targets must not be punctured by blades or any other part of the mower weighing more than 30g.

The purpose of this test is to ensure that if any part of the cutting system fails or comes into contact with anything that could cause damage, there is no hazard to the operator or anyone nearby.

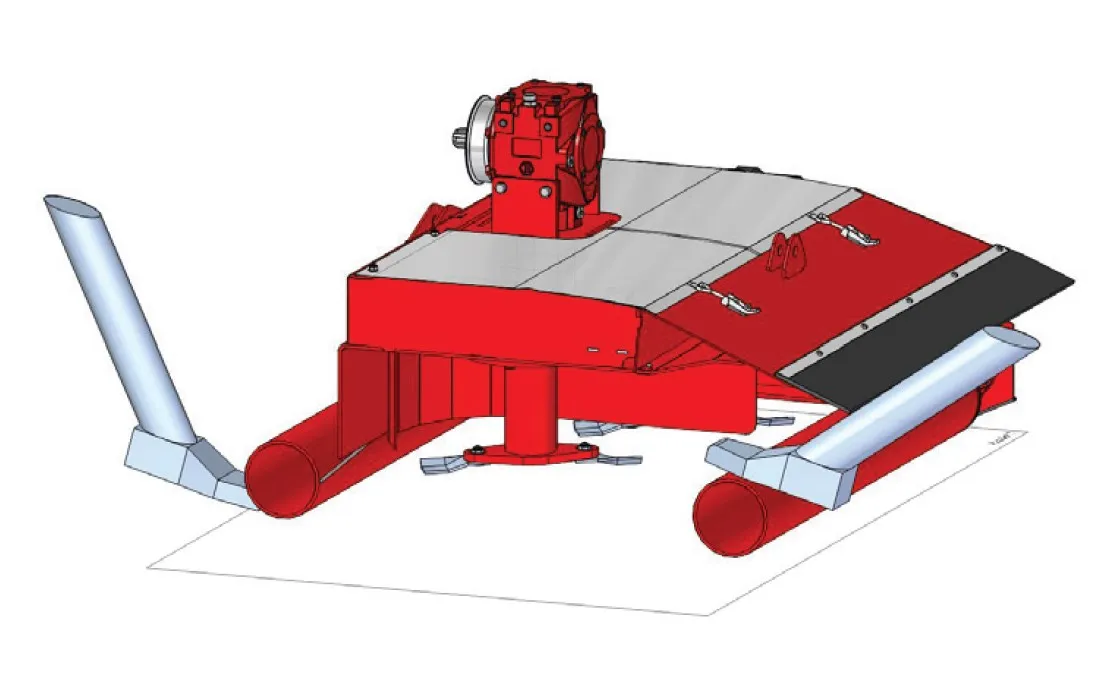

Designing and Testing for Finger and Limb Safety

Due to the nature of a mower, it’s imperative that fingers or limbs cannot get close to the blades, especially while in motion. For this reason, every hazard zone/ opening to moving parts has been carefully considered ensuring maximum safety.

Testing for Foot Access to the Cutting Chamber

Another important test is foot access. During testing, Trimax probes the cutting chamber with a dummy foot to evaluate the level of access around the machine, this ensures maximum protection for both the operator and any bystanders.

Trimax Mowers: Safer By Design

At Trimax, we’re not just meeting safety standards; we’re setting new benchmarks. Our relentless pursuit of safety excellence, coupled with innovative features and exhaustive testing, sets us apart from the competition. For further insights into the safety and testing procedures of Trimax mowers, please contact us at +64 7 541 0411.